We appreciate the trust that the Casa Riera Ordeix company has placed

in Refrica dryer equipment.

Casa Riera Ordeix is a benchmark worldwide, its products are found in the main stores and Delicatessen chains in the world.

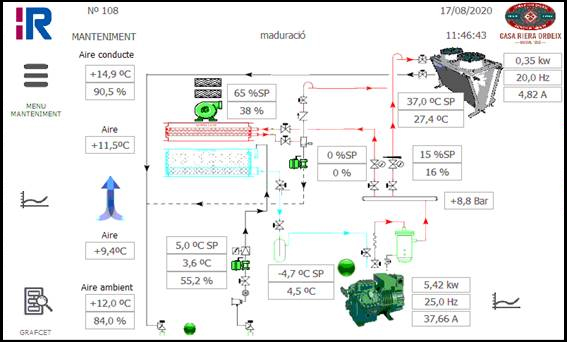

Refrica has just launched a new dryer concept, operating with a direct expansion system and achieving maximum energy efficiency, thanks to the floating evaporation control.

The autonomous type dryer has a frequency variator for the compressor, which always allows us to adapt the cooling capacity to the demand of the dryer .

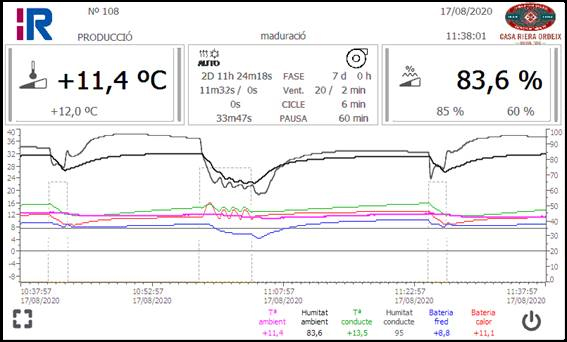

The dryer control continuously calculates the air outlet temperature of the cooling coil, reaching the necessary dew point based on the drying needs (temperature, humidity and process stage of the current recipe).

The control also calculates the heat needs at all times, to reach the level of aggressiveness, (temperature and humidity), of the air driven to the dryer and thus work in the optimal conditions for the treatment of the product with the most suitable air for each stage. of the drying process, adapting the performance of the dryer to each product and recipe.

The dryer also has EC fans, for an optimal adjustment of the air flow that allows us to optimize the distribution of air inside the dryer, achieving maximum homogeneity of the product within it.

The operation by recipes allows us to play with different flow rates for each of the phases according to the needs of the product, having the maximum degree of control of the process.

This system is as close as possible to the performance of a dryer operating with glycol water, the result is that the equipment works with the optimum DT, (Evaporation temperature / Air outlet temperature from the cold coil / Hot gas temperature / Hot gas outlet temperature). air from the heat battery), so as not to overdry and avoid creasing and other defects due to overdrying, or, on the contrary, lacing due to lack of drying.

We have also carried out an important innovation in the defrost system, thanks to a set of motorized dampers, we were able to recirculate the air through the cold coil, maneuvering with the motorized dampers we sectioned the impulsion ducts, preventing the effect of the defrost from affecting the conditions of the air from the dryer when it is carried out. Along the same lines, we have reduced defrost times to a minimum, this fact allows us a very high reduction in electricity consumption and a practically non-existent effect on the product.